Valve Components Manufacturer

Can’t Find What You’re Looking For?

Get A Quote

Download

Kuber Auto Pressing is a renowned manufacturer of valve components, specializing in producing high-quality and reliable parts for different applications. These components are essential for the proper functioning of engines, ensuring optimal performance and efficiency.

Kuber Auto Pressing utilizes advanced manufacturing techniques and cutting-edge technology to produce valve components that meet industry standards and customer requirements. We emphasize precision and accuracy in their production processes to ensure that each component performs flawlessly under demanding conditions.

Valve components manufactured by Kuber Auto Pressing are made from premium materials, such as high-grade metals or alloys, to ensure durability and longevity. These materials are carefully selected to withstand the extreme temperatures, pressures, and corrosive environments often encountered in engine systems.

The product range offered by Kuber Auto Pressing includes a variety of valve components, such as intake valves, exhaust valves, valve guides, valve seats, and valve springs. Each component is designed to fit specific engine configurations and undergoes rigorous quality control measures to ensure optimal performance and reliability.

Kuber Auto Pressing understands the importance of customization and works closely with customers to meet their unique specifications. The company’s skilled engineers and technicians provide technical support and expertise to assist clients in selecting the right valve components for their applications. Whether it’s a standard design or a custom-made solution, Kuber Auto Pressing strives to deliver products that meet or exceed customer expectations.

What are Valve Components?

Functions Of Valves components

- Stopping and starting flow

- Reduce or increase a flow

- Controlling the direction of flow

- Regulating a flow or process pressure

- Relieve a pipe system of a certain pressure

What Are Valves?

Classification Of Valves

- Linear Motion Valves : The valves in which the closure member, as in gate, globe, diaphragm, pinch, and lift Check Valves, moves in a straight line to allow, stop, or throttle the flow.

- Rotary Motion Valves : When the valve-closure member travels along an angular or circular path, as in butterfly, ball, plug, eccentric- and Swing Check Valves, the valves are called rotary motion valves.

- Quarter Turn Valves Some rotary motion valves require approximately a quarter turn, 0 through 90°, motion of the stem to go to fully open from a fully closed position or vice versa.

Types of Valve Components

Valve Body

Flange Ends

Socket Weld End

Buttweld End

Thread Connection

Valve Bonnet

Valve Disc

Valve Seat

Valve Stem

Valve Gasket

Valve Actuator

Valve Glands

Key Features of Valve Components

Flow Control

Versatility

Reliability

Flexibility

Safety

Energy Efficiency

Automation Potential

Process Optimization

Things to Consider When Selecting a Valve Component Manufacturer

1. Quality and Reliability

2. Customization Options

3. Industry Experience and Expertise

4. Excellent Customer Support

5. Competitive Pricing and Timely Delivery

Motion & Turne Of Valves

| Valve Types | Linear Motion | Rotary Motion | Quarter Turn |

|---|---|---|---|

| Gate | YES | NO | NO |

| Globe | YES | NO | NO |

| Plug | NO | YES | YES |

| Ball | NO | YES | YES |

| Butterfly | NO | YES | YES |

| Swing Check | NO | YES | YES |

| Diaphragm | NO | YES | NO |

| Pinch | YES | NO | NO |

| Safety | YES | NO | NO |

| Relief | YES | NO | NO |

APPLICATION INDUSTRY - Valve Components Manufacturer

Aerospace

Automobile

Bracket

Distillery

Electrical Appliance Hardware

Electronic Hardware

Frame Structures

Heaters

Metal Eyelet

Motors

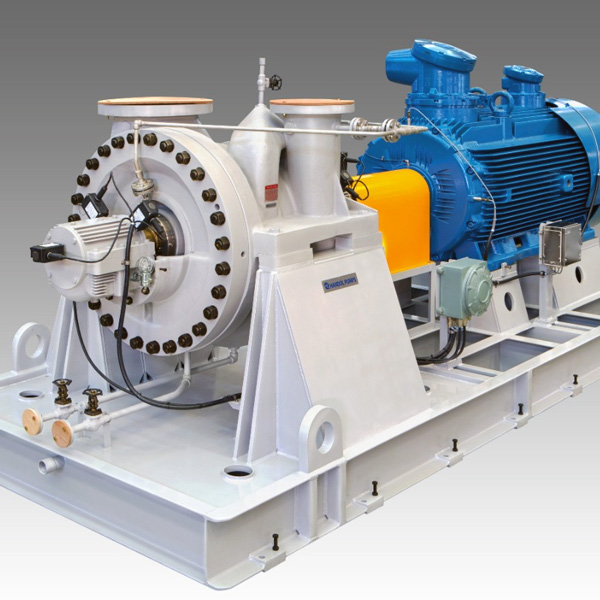

Pumps

Valves

Learn more about our Product Deep Draw Components Manufacturer

Get In Touch

FAQ

Yes, valve components can be customized to meet specific requirements. Customization may include material selection, dimensions, end connections, actuation options, and other features based on the application's needs. Contact Us